One-Stop Metal Fabrication Solutions

Investment Casting Manufacturer

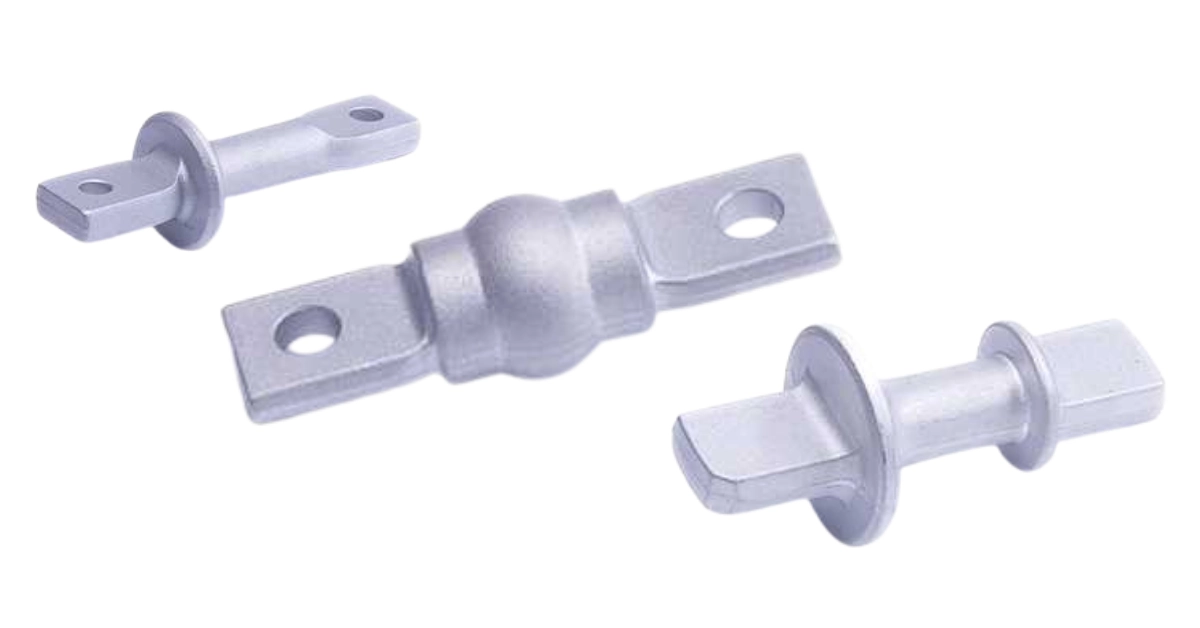

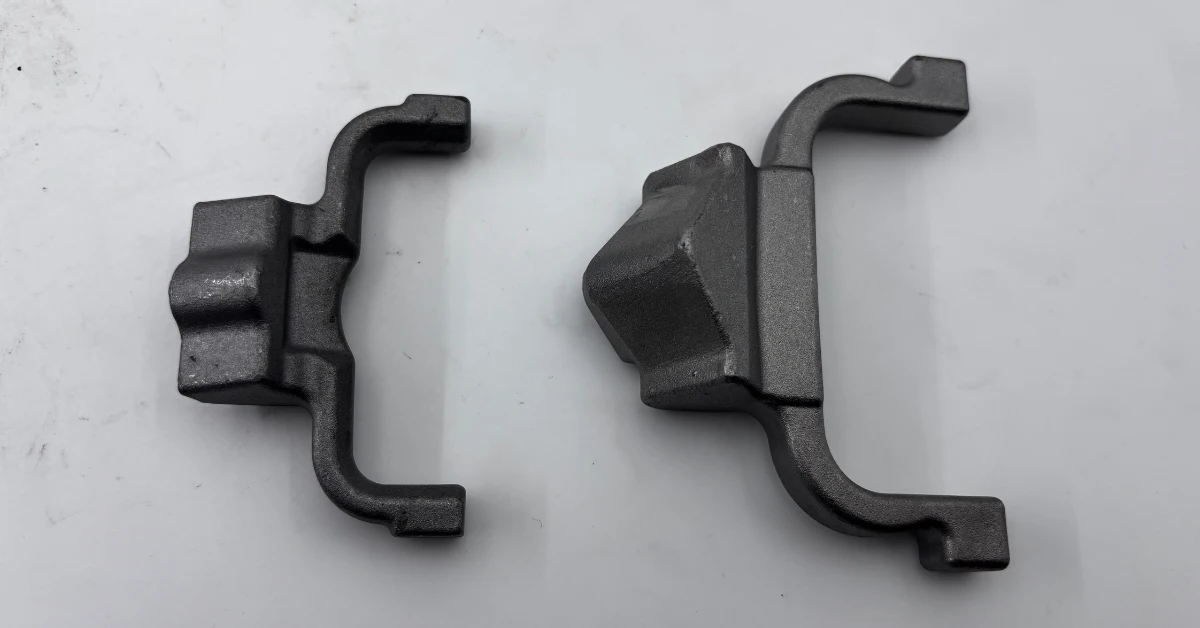

Precision Close-Die Forging

Why Choose HDC

More Than a Manufacturer: Your Engineering & Supply Chain Partner

A real project can be complicated and may require combining multiple manufacturing processes to fabricate the desired components. For brand manufacturers, managing multiple suppliers across different processes can quickly become complex and risky.

As a professional metal fabricator, we have continued to enrich our capabilities in manufacturing and developing our supply chain, aiming to provide one-stop solution for our customers.

With core strengths in casting, forging, and CNC machining, we bring together China’s top manufacturing resources under a single, reliable quality system. From engineering and sourcing to QC and logistics, we handle the complexity—so you can focus on your product, not your suppliers.

HDC Core Capabilities

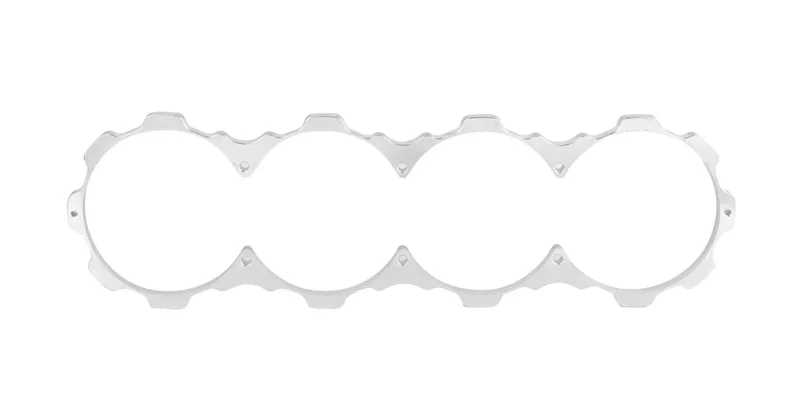

Metal Casting Service

- Precision casting with stainless steel, nickel alloy, and more.

- 50 kg maximum single casting.

- Tight tolerance with CNC finishing.

- Custom solution in casting processes, material configuration, and heat treatment.

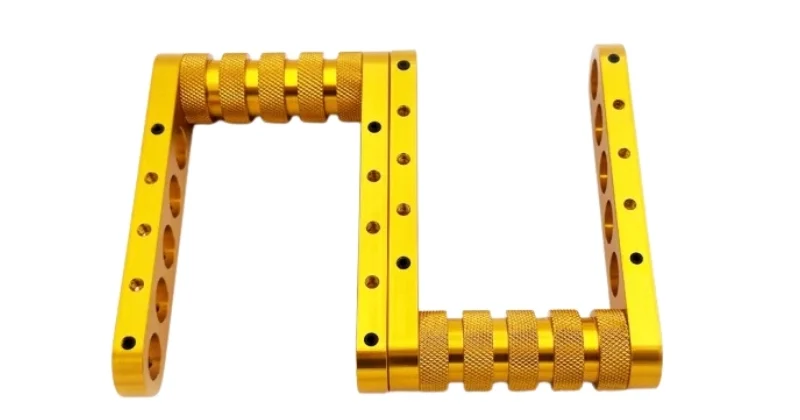

Metal Forging Services

- Forging with aluminum alloy, carbon steel, and stainless steel.

- 30 kg maximum single forging.

- 160T ~ 4000T forging presses and screw presses.

- Cold forging and hot forging are available.

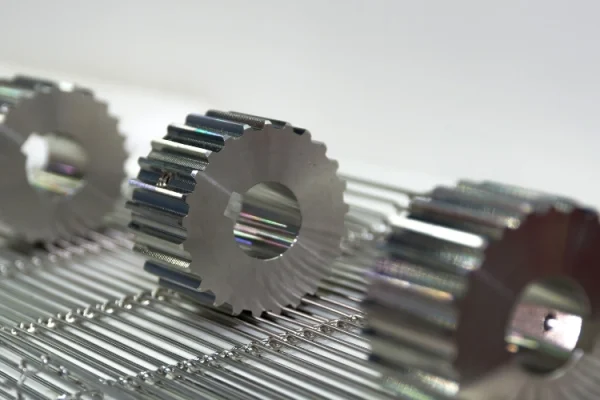

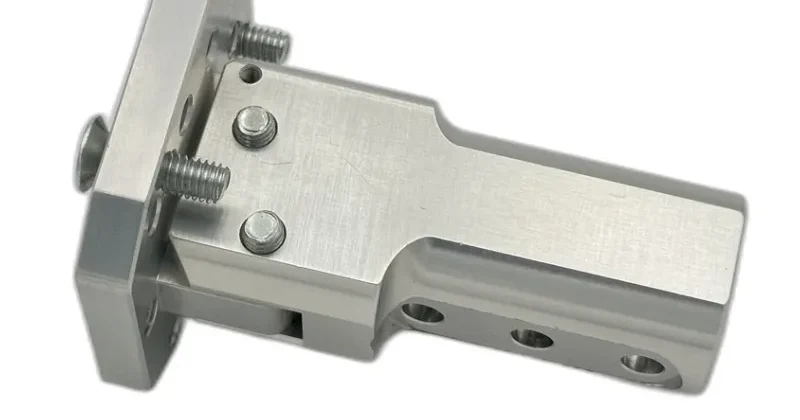

CNC Precision Machining

- Equipped with 3-axis, 4-axis, and 5-axis CNC machining centers.

- Tight tolerance up to ±0.005 mm.

- CNC finishing critical dimentions for castings and forgings.

- Critical dimension control.

Global Service

We served over 1000 clients from 50+ countries.

ISO & IATF Certified

We have the certification of ISO9001:2005.

50+ Certified Materials

We can customize your metal parts with over 50 types of different materials

On-Time Delivery

The parts will be delivered to you as promised, from 1 week to 30 days.

For more information, please visit our Service Policy page.

Elevate Your Brand with HDC's Custom Solutions

At HDC, we go beyond manufacturing. We work as a practical, hands-on partner to help bring your product ideas into production. From early concepts to finished components, we support custom metal parts and precision machining for growing and established brands alike.

With integrated casting, forging, and CNC machining, we help you move faster, reduce supply chain complexity, and achieve consistent quality—so you can focus on building your brand, not managing suppliers.

Our ordering process

Initial Consultation

Share your project requirements with our team. We’ll review your application and provide practical engineering input to help you get started.

Design Submission

Send us your design files, or work with our engineers to refine the design for manufacturability and cost efficiency.

Quote and Design Review

You’ll receive a clear, detailed quotation along with a final review of all specifications before moving forward.

Prototype Development

When required, we produce prototypes to validate the design, fit, and performance before mass production.

Production and Quality Control

Once approved, full-scale production begins, supported by in-process inspections and strict quality control at every stage.

Shipping and Delivery

Choose your preferred shipping method. We arrange worldwide delivery with reliable lead times.

Access our resources to learn more about HDC’s capabilities.

Metal Materials We Work With

We work with a wide range of metal materials to support different strength, weight, and performance requirements.

Comprehensive Surface Treatment Options

With integrated in-house surface finishing and a reliable post-treatment supply chain, we provide a full range of surface treatments to enhance appearance, durability, and functional performance of custom metal parts.

| 🔷 Sand Blasting | 🔷 Bead Blasting |

| 🔷 Type Ⅱ Anodizing | 🔷 Type Ⅲ Anodizing |

| 🔷 Podwer Coating | 🔷 Painting |

| 🔷 Zinc Plating | 🔷 Chrome Plating |

| 🔷 Laser Engraving | 🔷 Black Oxide |

Heat Treatment for Metal Parts

Heat treatment plays a critical role in achieving the required strength, hardness, and durability of metal parts.

With controlled heat treatment processes and a reliable post-treatment supply chain, we support a full range of heat treatment options to optimize material properties for different applications.

| 🔷 Quenching | 🔷Tempering |

| 🔷 Annealing | 🔷Normalizing |

| 🔷 Solution treatment |

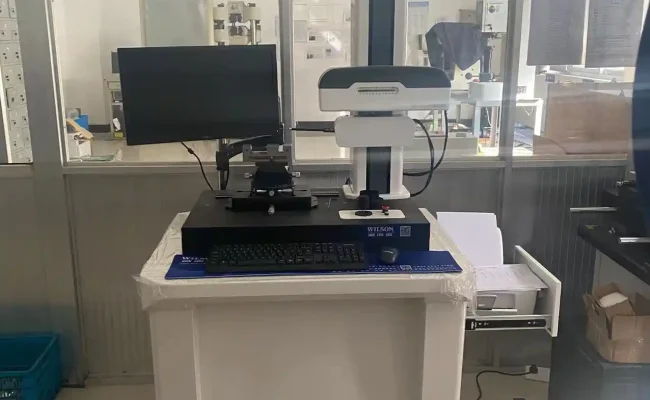

Quality Control

Our Custom Manufacturing Products

Forged, cast and CNC machined components for multiple industries

Forged Automotive Components

Forged Motorcycle Components

Steering & Wheel Accessories

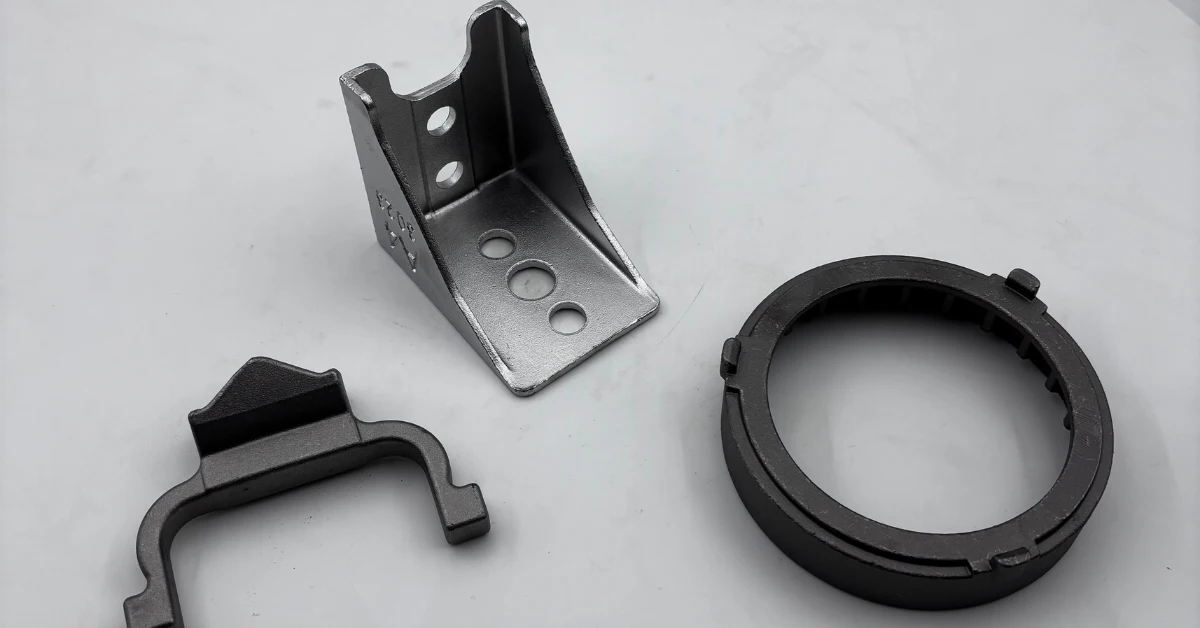

Forged Structural & Tooling Components

Tools, brackets and Fittings

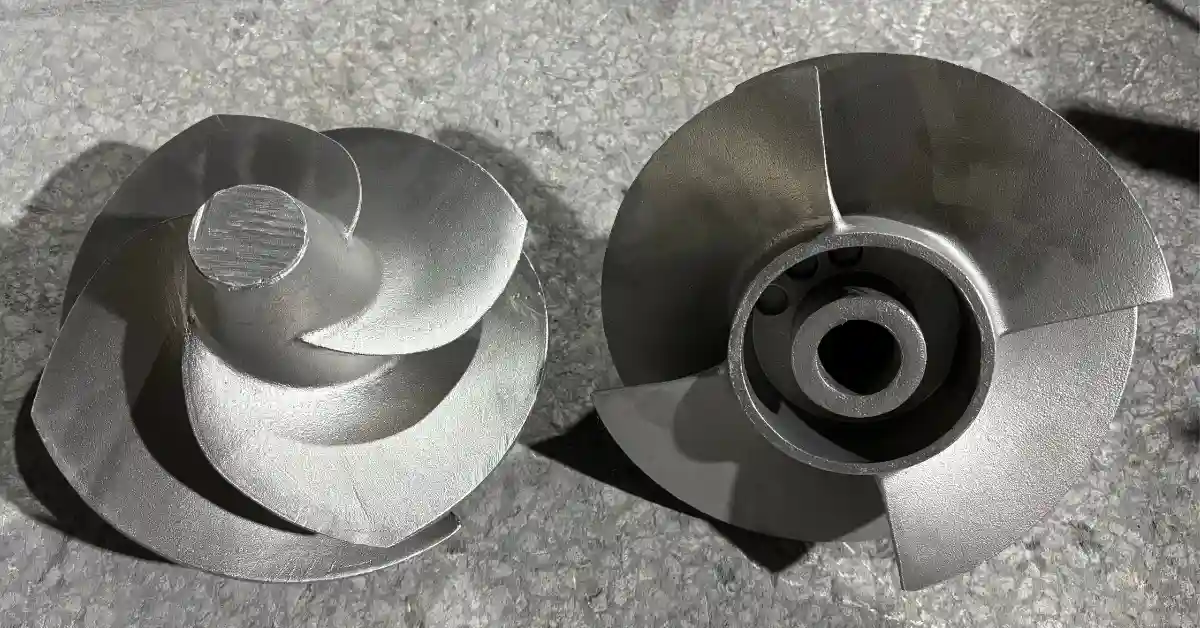

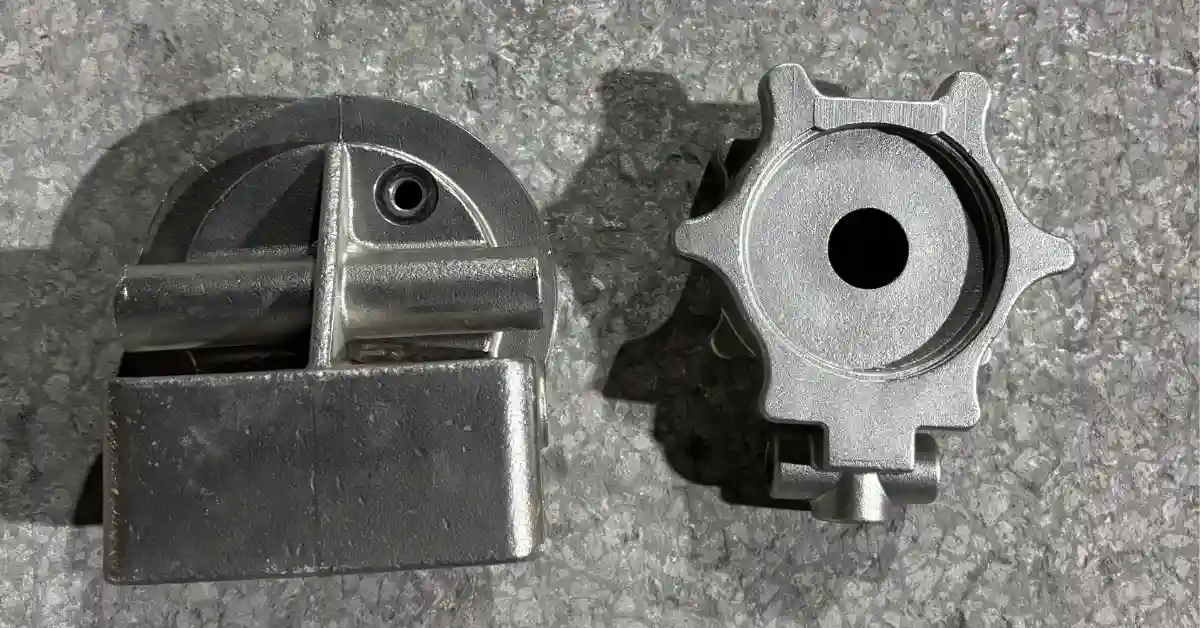

Industrial Casting Components

Pump Body, Valve, Gear Housing

Vehicle Casting Parts

Car, Motorcycle, Bicycle, E-bike Parts

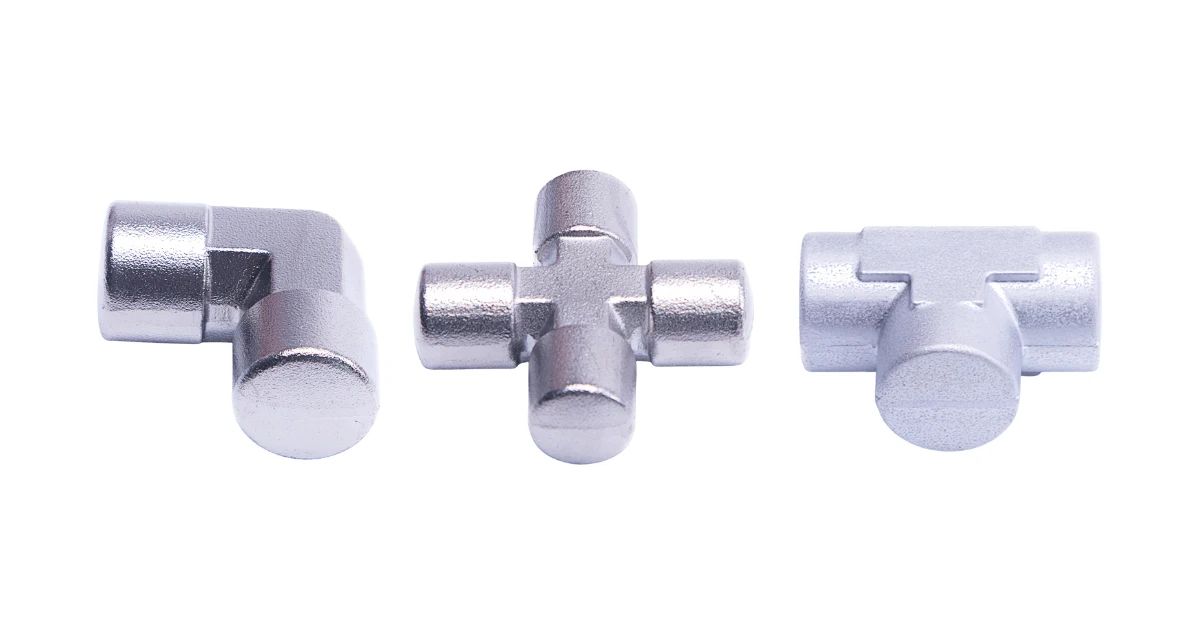

Hardware & Structural Castings

Connectors, brackets and custom hardware

What Our Clients Say

Frequently Asked Questions

Everything you need to know before working with HDC.

How do I request a quote?

To request a quote, simply share your project details with us, including drawings, material requirements, and any special specifications. Our engineering team will review your information and provide a clear, detailed quotation as quickly as possible.

What is the typical lead time for custom orders?

Lead times vary depending on part complexity, quantity, and manufacturing processes. For most custom projects, production can be completed within a few weeks. Estimated lead times are confirmed during the quotation stage.

What are the shipping options available?

We offer flexible shipping options, including air freight, sea freight, and express delivery. Worldwide shipping is available, and FOB terms can be arranged based on your requirements.

How does HDC ensure product quality?

Quality is controlled at every stage of production. From raw material inspection to in-process checks and final inspection, our quality system is supported by ISO certification to ensure consistency and reliability for every order.

Is there a minimum order quantity(MOQ)?

MOQ depends on the product type, material, and manufacturing process. We support flexible production volumes and encourage you to contact us to discuss the most suitable solution for your project.

Can HDC help with design or prototyping?

Yes. We provide engineering support and prototyping services to help optimize your design for manufacturability, performance, and cost before mass production.

What payment methods do you accept?

We accept secure payment methods including bank transfers, PayPal, and other commonly used options. Payment terms are confirmed during the order process to ensure clarity and transparency.

Do you provide support for first-time importers?

Yes. We regularly work with first-time importers and provide guidance on Incoterms, customs clearance, and shipping options to help ensure a smooth import process.

How can I contact HDC for more information?

You can reach us through our contact page, email, or phone. Our team is ready to discuss your project and answer any questions you may have.

Bring Your Metal Parts from Concept to Production

Work with a one-stop metal fabrication partner covering casting, forging, and CNC machining. From engineering support to final delivery, HDC helps you simplify sourcing and reduce risk.

* Engineering review available. NDA can be signed upon request.